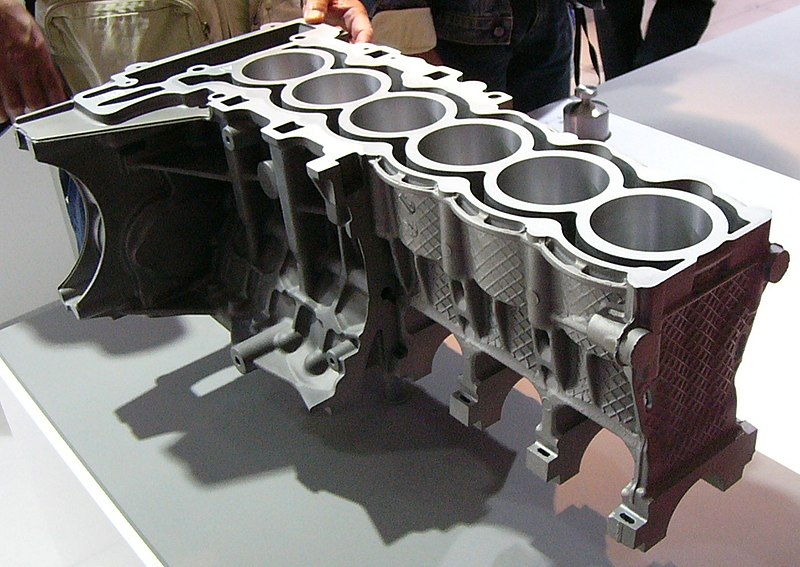

Diecasting in Malaysia has become an essential component of the nation's production market, contributing to different industries such as automobile, electronics, and consumer goods. As one of the most effective and precise techniques of creating steel components, diecasting has gotten grip due to its capacity to develop complex shapes with high precision and very little waste. The process includes injecting molten steel right into a mold under high pressure, producing very comprehensive parts that fulfill the strict top quality requirements required by various sectors. This write-up explores the surge of diecasting in Malaysia, examining its growing value, the industries it serves, and the benefits it gives producers and consumers alike.

Among the major factors diecasting has actually prospered in Malaysia is due to its extraordinary capacity to produce high-precision parts cost-effectively. In sectors such as vehicle and electronic devices, where accuracy is vital, diecasting offers manufacturers with the devices needed to create elements with complex geometries and smooth surface areas. This technique removes the need for extensive post-production job, such as machining, decreasing both material waste and production time. The process is specifically appropriate for creating components that need to be light-weight yet solid, which is essential for industries like automobile, where minimizing weight can bring about far better gas performance and efficiency. As the need for high-performance parts boosts, the adaptability and efficiency of diecasting continue to make it the preferred technique for producing complicated elements.

The benefits of diecasting are countless, and they make the procedure specifically appealing for automation of components. Among the major advantages is the capacity to generate complex forms with high accuracy. This is especially beneficial for markets such as auto and aerospace, where components have to fulfill strict efficiency standards. Diecast parts are usually solid, light-weight, and immune to put on, making them ideal for applications that require longevity and integrity. The process additionally minimizes the demand for additional machining, as diecast parts often appear of the mold and mildew with a smooth surface area coating and limited tolerances. This performance decreases production time and prices, which is extremely beneficial in industries that require to manufacture huge amounts of parts swiftly and cost-effectively.

The diecasting industry in Malaysia is not almost creating components; it additionally entails embracing cutting-edge modern technologies to enhance manufacturing performance. As industries remain to require better, quicker production times, and much more intricate components, diecasting producers in Malaysia have actually embraced automation and progressed robotics. Automation permits exact control over the diecasting process, lowering human mistake and improving consistency in manufacturing. Making use of robotics for tasks like mold and mildew handling, metal injection, and part elimination additionally enhances the efficiency of the process. Additionally, Malaysia's diecasting sector has actually incorporated innovative products such as aluminum, zinc, and magnesium alloys, which are lighter and more powerful than conventional products. These improvements guarantee that Malaysian manufacturers can create high-performance elements that fulfill the advancing needs of global markets. To find extra details kindly visit Senadiecasting

The growth of diecasting in Malaysia is additionally sustained by a strong export market. As the country's diecasting capabilities enhance, more Malaysian manufacturers can meet the demands of worldwide customers. Malaysia exports diecast items to a variety of areas, including The United States and copyright, Europe, and Asia, with a certain concentrate on the automobile, electronic devices, and durable goods industries. The country's credibility for producing premium, exact parts has made it an appealing partner for worldwide companies aiming to resource trustworthy parts. Malaysia's trade contracts with numerous countries and its membership in regional companies such as Organization of Southeast Asian Nations have further enhanced its setting as an export center for diecast items. As worldwide demand for diecast components remains to expand, Malaysia is well-positioned to maximize this possibility and enhance its share of the international market.

However, like lots of producing markets, the diecasting market in Malaysia deals with obstacles that need to be addressed to make sure continued growth and sustainability. One of the primary challenges is the rising expense of resources, especially metals such as aluminum and magnesium, which are essential for diecasting. Changes in international metal rates can affect the earnings of makers and make it challenging for companies to preserve affordable prices. To minimize this, several diecasting companies in Malaysia are checking out alternative materials and recycling alternatives to minimize material prices and reduce waste. Furthermore, environmental worries have actually triggered the sector to adopt more sustainable methods, such as lowering power intake and enhancing waste administration in the diecasting procedure. By accepting sustainability, the Malaysian diecasting industry can continue to thrive while adding to international initiatives to reduce ecological influence.

Comments on “The Rise of Diecasting in Malaysia: Improvements and Industry Growth”